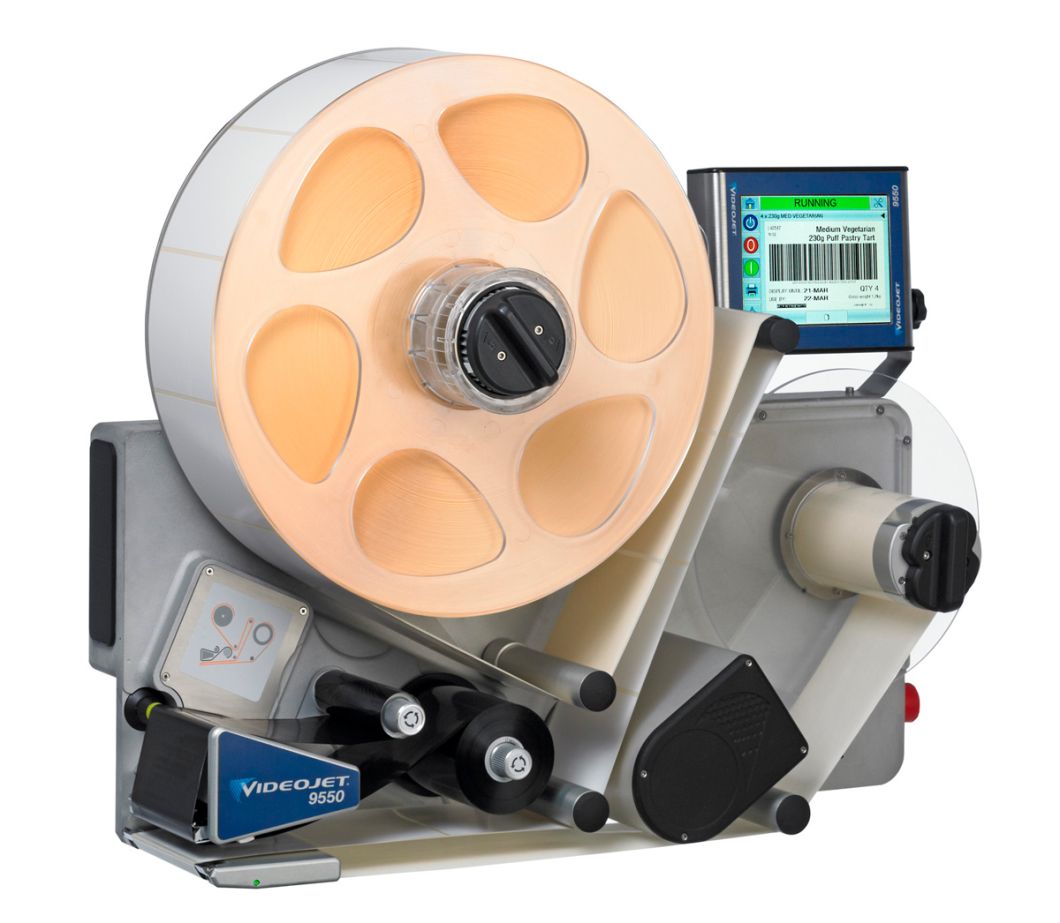

Videojet 9550 Label Print & Apply System (LPA)

The Videojet 9550 Label Print & Apply System (LPA) was discontinued in September of 2024. Supplies and parts sales for the Videojet 9550 will be available through December 31, 2029*.

Support for customers with an installed Videojet 9550.

- Download the 9550 operator manual

- Download the 9550 spec sheet

- Get technical support

- Get service support

- Find a replacement printer

For more information, please contact your Videojet Sales Engineer.

*Note: Although Videojet will take commercially reasonable efforts to provide spare parts as specified, in certain cases outside Videojet’s control, some parts may not be available for discontinued products.